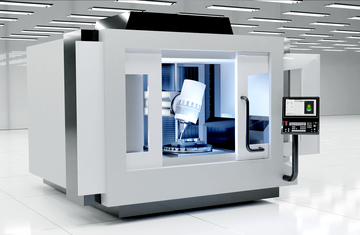

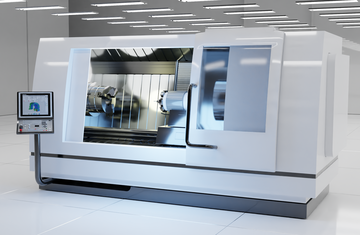

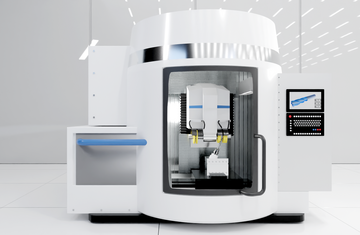

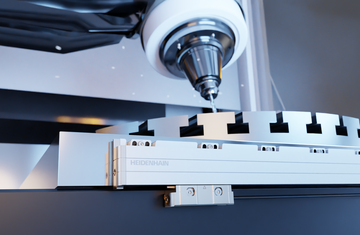

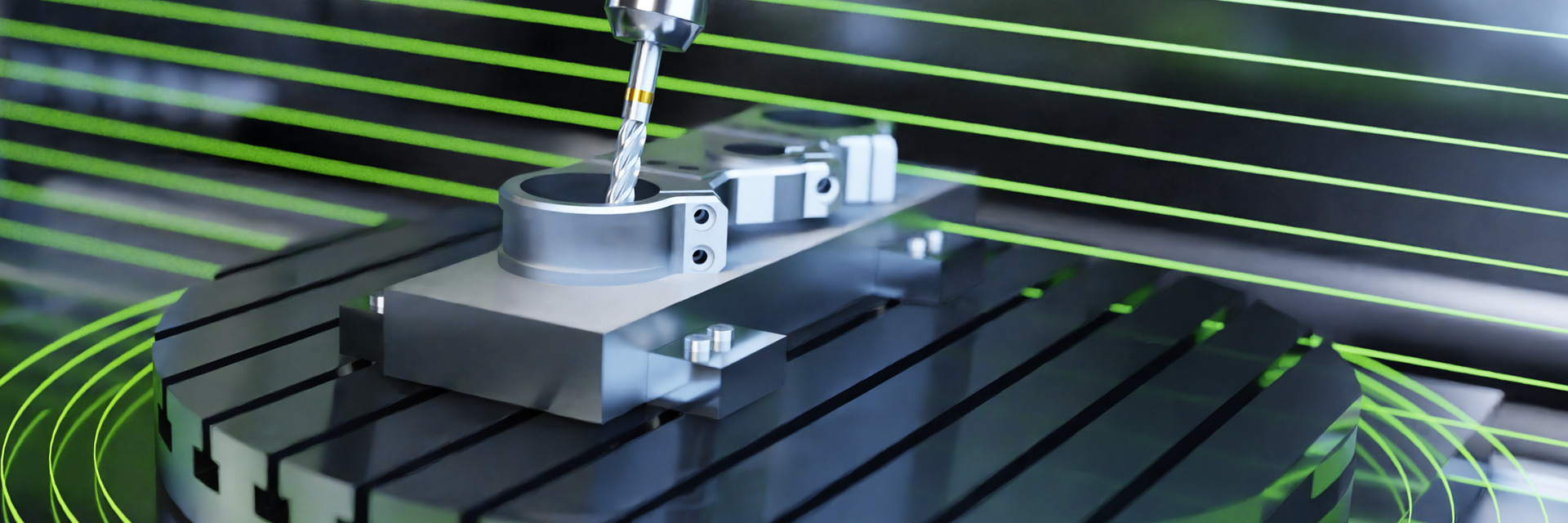

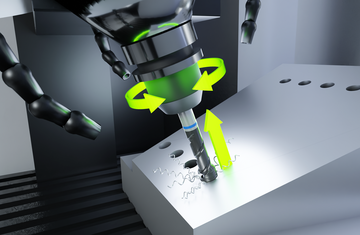

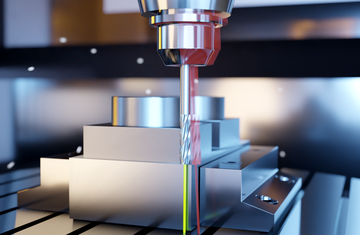

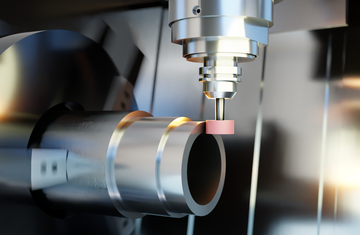

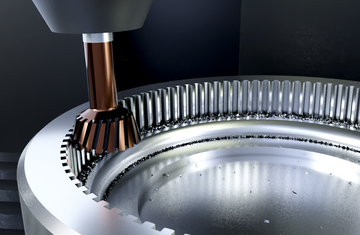

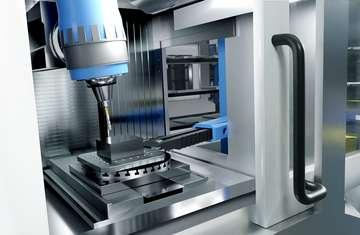

Rotary encoders, angle encoders, and linear encoders position rotary and linear axes with extreme accuracy. Grid encoders and touch probes measure the machine, workpiece, or tool. Motors, drives, and controller technology accurately and dynamically move axes and tools along the desired path. Milling and turning controls provide the shopfloor user with exceptional support in solving a wide variety of machining challenges.

TNC Club: efficient learning opportunities for control operators

The TNC Club is the meeting point for experts, with extensive learning opportunities to help users of HEIDENHAIN controls perform machining operations more efficiently.

Club members benefit from special training courses, events, and workshops for deepening their knowldge of controls.

Find out more about automation

Many automation solutions utilize HEIDENHAIN products such as the innovative KCI 120 Dplus dual encoder for motor feedback and position measurement, all in a single rotary encoder for advanced robotics applications. Visit these pages to discover more about it, along with many other products and applications: