Solutions for wind turbines

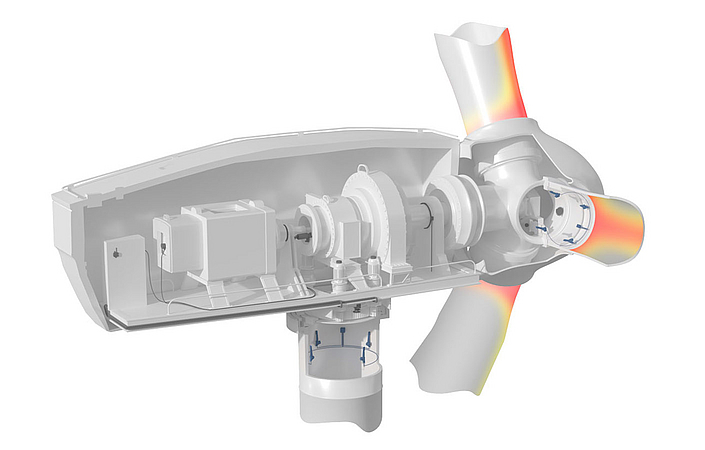

Wind turbines may look similar on the outside, but the way they generate power behind the walls of their nacelle varies.

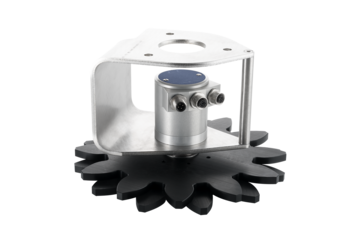

Wind turbines equipped with a gearbox can leverage the many benefits of a high-speed generator. These generators are compact and rotate much faster than the rotor. The results are greater efficiency and an electrical frequency that matches the power grid.

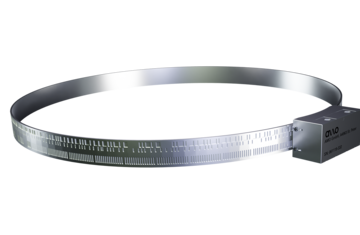

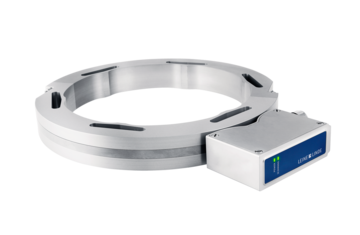

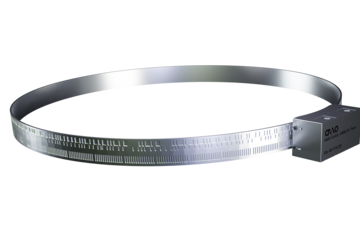

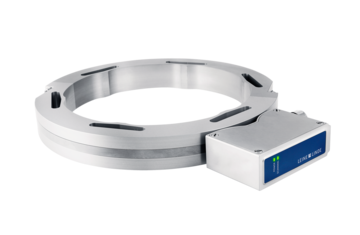

Wind turbines without a gearbox are more compact and contain fewer moving parts. But these benefits are offset by an expensive ring generator requiring ever greater weight for higher performance. Even for these generators, we provide relialbe and easy-to-install modular encoders with very large diameters.

To discover sensors and encoders designed for geared and gearless wind turbines, explore the products from HEIDENHAIN, AMO, LEINE LINDE and LTN below.