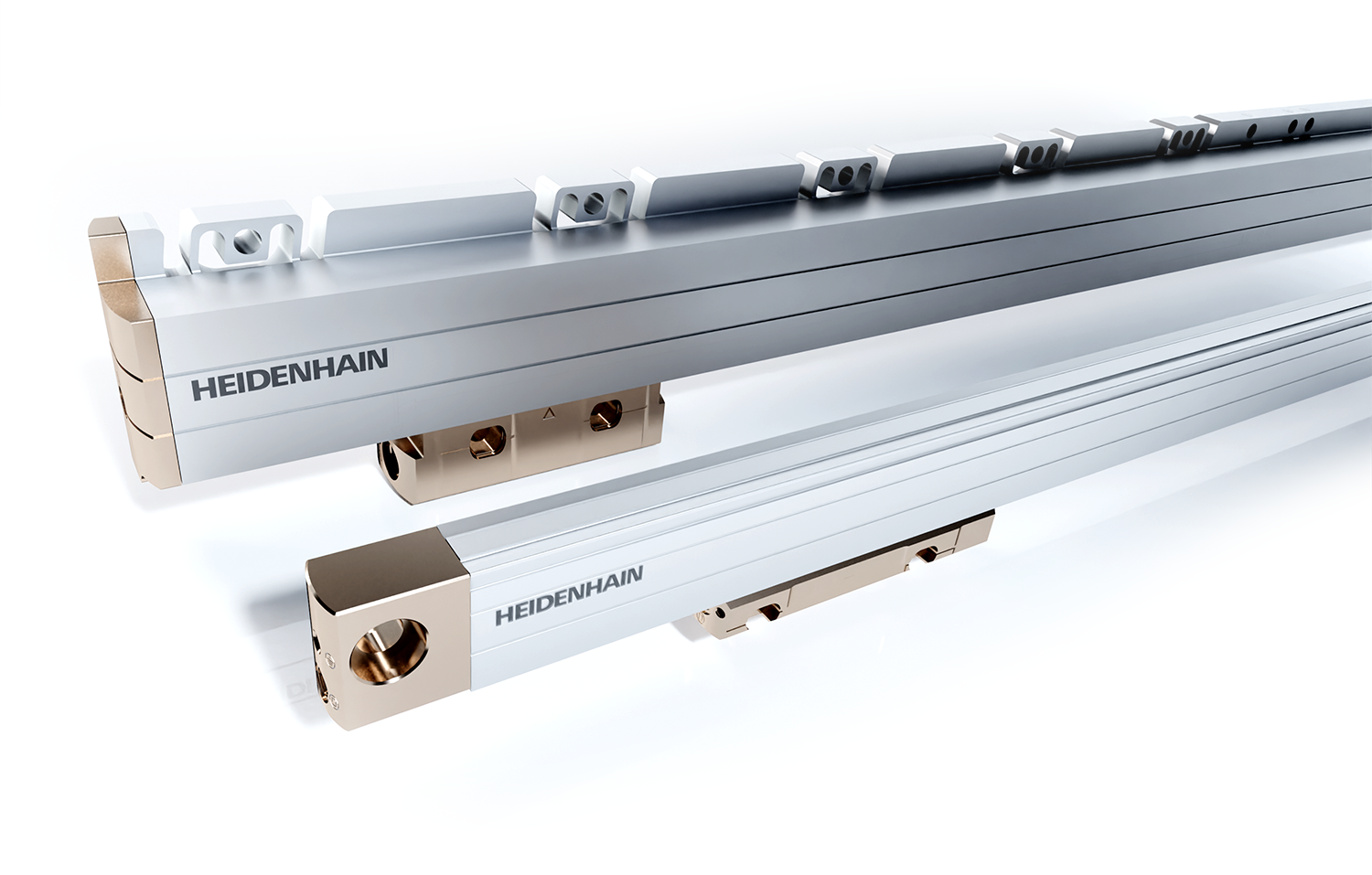

These solutions include versatile, user-friendly TNC controls for milling machines, milling-turning machines, and machining centers, along with digital readouts for manually operated machine tools. Linear and angle encoders from HEIDENHAIN handle direct motion measurement within closed loop control systems.

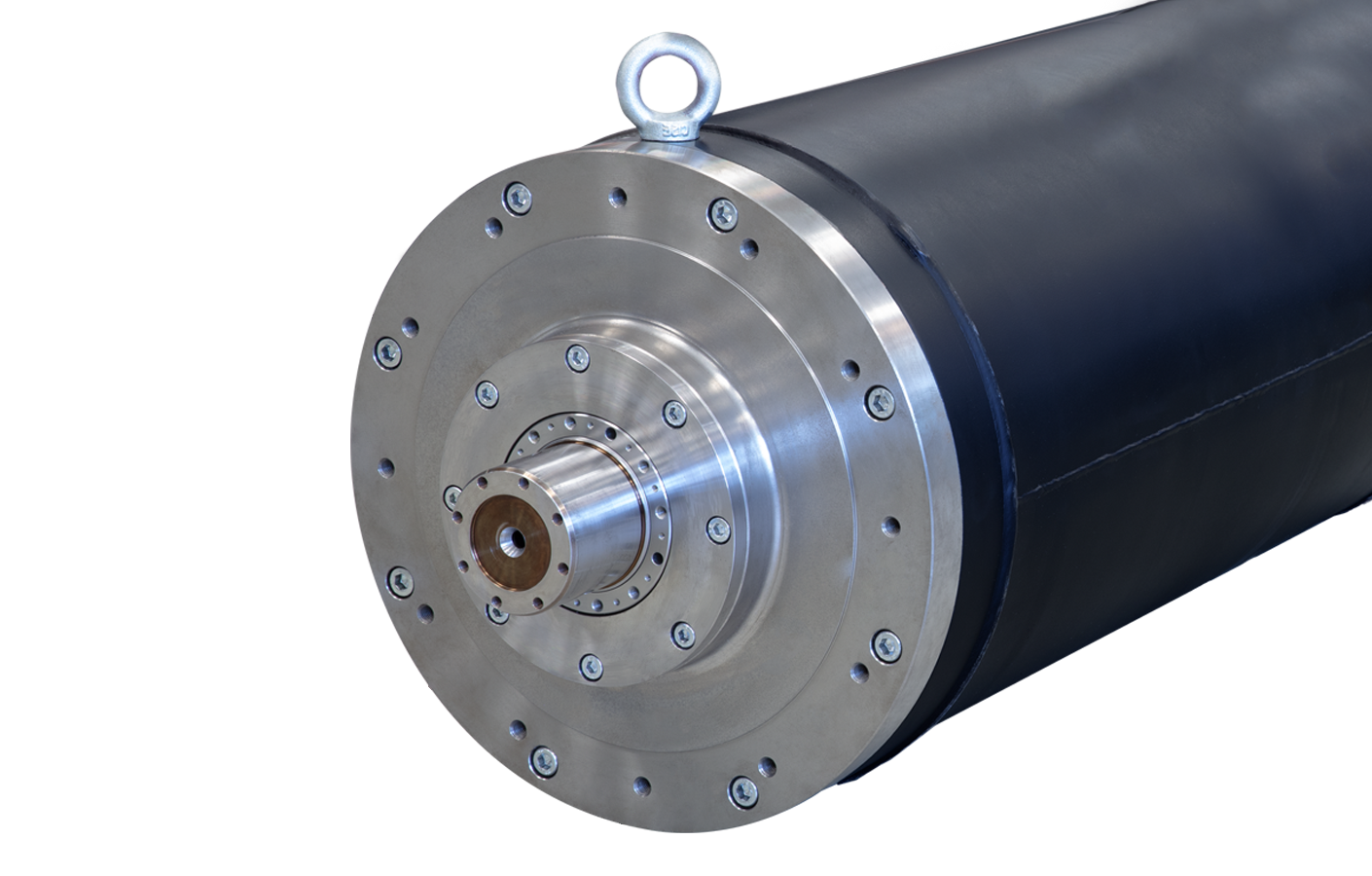

The new Gen 3 drives are also ideal for milling machines, offering state-of-the-art interface technology, excellent performance specs, and very high controller performance. Motors are available from HEIDENHAIN and ETEL.

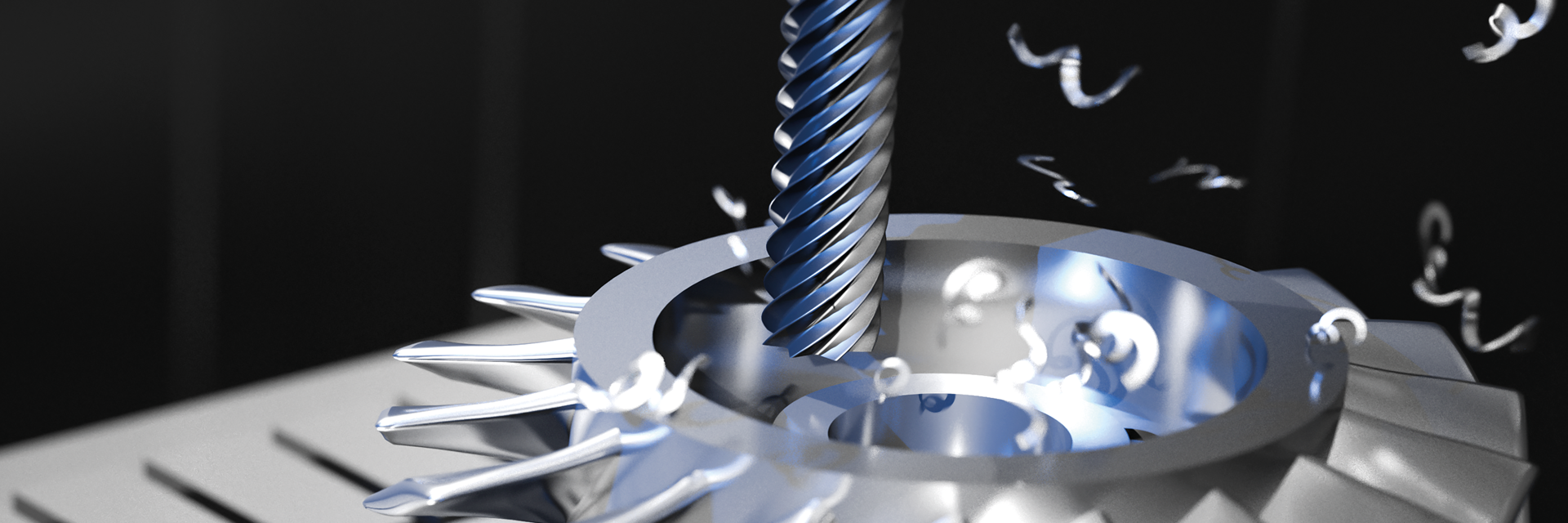

TNC controls enable shop-friendly conversational language programming for numerous machining tasks, making them the go-to choice for machine tool users. Touch probes, camera systems, and electronic handwheels are also practical aids for reducing setup times and increasing process reliability. Programming stations let users of HEIDENHAIN controls create, test, and optimize their NC programs in the office away from shopfloor distractions.