AI-supported flank-wear measurement with VT 122 and Visual Tool Check

Discover intelligent and innovative solutions for machine tools and production automation: “Empower Manufacturing” is this year’s motto for HEIDENHAIN and its brands AMO, ETEL, NUMERIK JENA, and RSF at the EMO 2025 trade show in Hannover, Germany. Showcasing exciting new solutions and product enhancements, HEIDENHAIN and its brands are empowering users and machine manufacturers to produce with even greater efficiency and agility.

The VT 122 camera and the Visual Tool Check software form a measuring system for holistic evaluation of tools. They combine three tasks in one system: tool presetting, tool magnification, and visual tool inspection. The act of image generation by the VT 122 within the machine's work envelope is fully integrated into the machining process. Version 1.6 of the Visual Tool Check software, with automated and AI-supported flank-wear measurement, makes it possible to evaluate the images right on the control’s screen or an office PC, without a trip to the measuring lab.

Benefits provided by this system, which consists of the VT 122 measuring camera and the Visual Tool Check software, include very specific information about the status of the tools in the machine. That way, the machine operator can take full advantage of each tool's service life. At the same time, process reliability is increased, since damage to the tool, workpiece, and machine is avoided, and machining accuracy becomes better due to the use of tools with intact geometries. This contact-free tool inspection also reduces machine downtime, since the images from the work envelope go directly to the control's screen or a PC without interrupting the machining process.

In combination with the new Visual Tool Check 1.6 software, the VT 122 camera makes AI‑supported wear measurement possible, which automates previously manual processes. This rapid process documentation is integrated into the machining operations, and is thus a key benefit for industries such as aerospace and medical tech. The VTC cycles make it very easy for the operator to direct the AI-supported wear-measurement process. The NC control slowly rotates the tool directly in front of the camera. The result is a panoramic image of the tool that includes all of its flutes. The Visual Tool Check 1.6 software then automatically determines the flank wear.

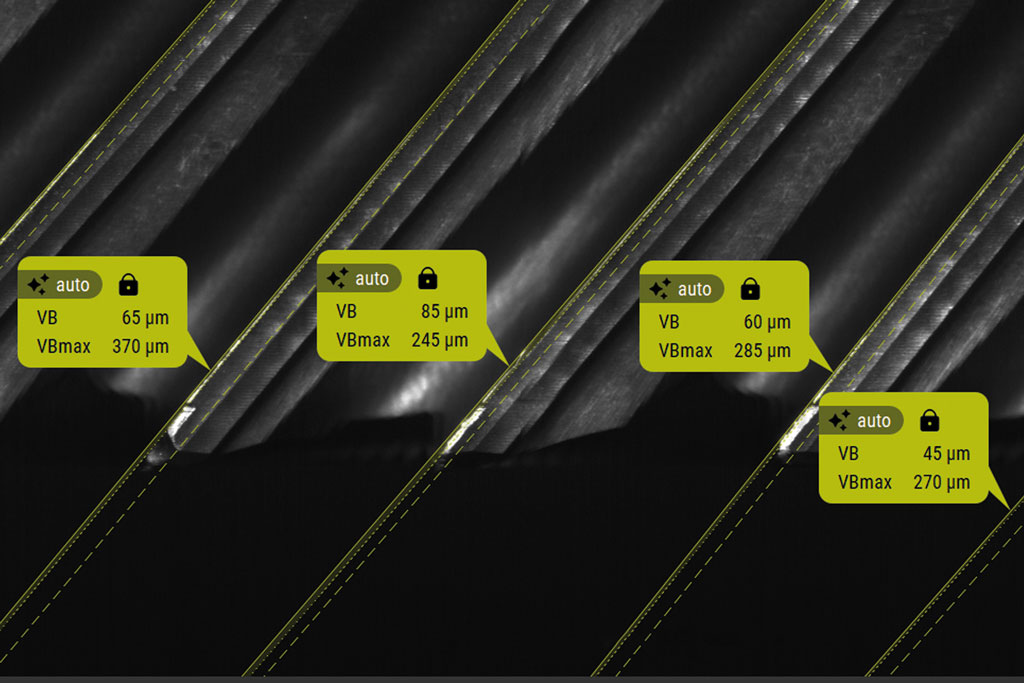

The AI-supported results are shown clearly and concisely: Each flute is analyzed individually, with both the maximum and average values shown and automatically stored. The operator can also define individual warning values and tool-disabling values, visualize how tools become worn over time, and export this information to CSV files for further analysis. This makes the VT 122 camera and the Visual Tool Check 1.6 software from HEIDENHAIN the primary solution for automated tool-wear measurement on machine tools.